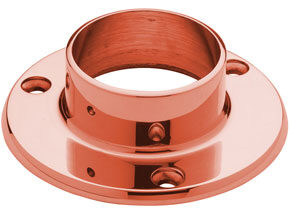

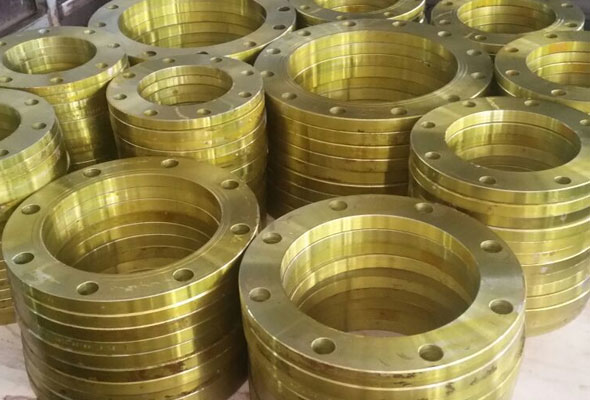

Ample Alloys is a globally accepted Manufacturers and Exporter of ASTM A151 Cu-Ni 90/10 Weld Neck Flange, Class 150 Copper Nickel 90/10 Orifice Flanges, Copper Nickel 90/10 Ring Spacer Flange, Grade 90/10 Spectacle Blind Flange, Copper Nickel 90/10 Threaded Flange, Cu-Ni 90/10 Blind Flange, Copper Nickel 90/10 RTJ Flange, Werkstoff Nr 2.0872 Slip On Flange.

Table of Content

- ASTM A151 Copper Nickel 90/10 Slip On Flange Specifications

- UNS C70600 Orifice Flange Chemical Composition

- WERKSTOFF NR. 2.0872 Weld Neck Flange Mechanical Properties

- ASME SA151 Copper Nickel 90/10 Threaded Flanges Equivalent Material Grades

- Cu-Ni 90/10 Industrial Flange Types

- Copper Nickel 90/10 Similar Products

- Cu-Ni 90/10 Blind Flange Applications

- In Stock Copper Nickel Flanges Grades

- ½” – 24” Flanges Weight Chart

- ANSI B16.5 Flanges – Dimensional Tolerances

- Industrial Flanges Dimensions ANSI B16.5

Mumbai, India-based Suppliers of Copper Nickel 90/10 Lap Joint Flange. Flange Specification, Prices, Application, Dimensions in MM, Weight, Material, Advantages, Temperature Limitation, Drawing, Thickness, Standards, Types, Schedule, Pressure Rating, Bolt Chart. Get Best Price List of ASTM A151 Cu-Ni 90/10 Flanges in Latin America, Dubai, Canada, Kuwait, USA, Italy, Qatar, Australia, Japan, and UK.

Copper Nickel 90/10 Flanges Specifications

- Flange Size Range: NPS 1⁄₂” To NPS 48”

- Specifications: ASTM A151 / ASME SA151

- Grades: 90/10 / 2.0872 / UNS C70600

- Class: PN6, PN10, PN16, PN25, PN40, PN64 etc.

- Pressure Rating: Class 150(lb), Class 300(lb), Class 600(lb), Class 900(lb), Class 1500(lb), Class 2500(lb)

- Standards: ANSI B16.5, ANSI B16.47 Series A & B, ASME 16.36, MSS SP44, ASA, API-605, AWWA, ISO-70051, JIS B2220, EN1092, BS 10

- International Specifications: WERKSTOFF NR. / UNS / JIS / BS / GOST / AFNOR / DIN / EN

- Test Certificates: Raw Materials Certificate, EN 10204/3.1B, Third Party Inspection Report, 100% Radiography Test Report

- Shapes and Types: RTJ-Ring Type Joint, LMF-Large Male-Female, FF-Flat Face, Small Tongue, SMF-Small Male-Female, RF-Raised Face, Large Tongue & Groove, Groove, LJF-Lap-Joint Face

- Production Technique: Forged / Heat treated and machined

Copper Nickel 90/10 Flanges Chemical Composition:

| Grade | 90/10 |

|---|---|

| Cu | 88.6 min |

| Mn | 1.0 max |

| Pb | 0.05 max |

| Ni | 9-11 max |

| Fe | 1.8 max |

| Zn | 1 max |

Copper Nickel 90/10 Flanges Mechanical Properties:

| Element | 90/10 |

|---|---|

| Melting Point | 2260 F |

| Density | 0.323 lb/in3 at 68 F |

| Tensile Strength | 50000 psi |

| Elongation | 30 % |

| Yield Strength (0.2%Offset) | 20000 psi |

Copper Nickel 90/10 Flanges Equivalent Material Grades:

| UNS | WERKSTOFF NR. |

|---|---|

| C70600 | 2.0872 |

Cu-Ni 90 / 10 Flanges is well-known for some of the most important industries and applications due to its accurate variety of qualities. This steel’s applications include gas turbine additives and cryogenic storage tanks, jet engines, pump bodies and components, rocket vehicles, and thrust reversers, nuclear gas detail spacers, and hot extrusion tooling. If the provider temperature is less than 1100 degrees F, hot-cold working in the range of 1700 degrees F to 1850 degrees F (927 degrees C to 1010 degrees C) will improve forging strength (593 Degrees C).

Ample Alloys is a known exporter and distributor of Cupro nickel 90 / 10 Flanges, which is resistant to oxidation at some point in its advantageous temperature range. This steel was hot-operated at a maximum furnace temperature of 2050 degrees Fahrenheit (degrees Celsius). It is commonly purchased in the solution annealed temper, but it may be ordered aged, cold worked, or both cold worked and aged. We provide this product to our customers with custom-built specifications that meet their needs.

Copper Nickel 90/10 Flanges Types

- Cupro Nickel 90/10 Spectacle Blind Flanges

- Cupro Nickel 90/10 Paddle Blind Flanges

- Cupro Nickel 90/10 Orifice Flanges

- Cupro Nickel 90/10 Threaded Flanges

- Cupro Nickel 90/10 Nipoflange

- Cupro Nickel 90/10 Ring Spacer Flanges

- Cupro Nickel 90/10 Slip on Flanges

- Cupro Nickel 90/10 Weld Neck Flanges

- Cupro Nickel 90/10 Forged Flange

- Cupro Nickel 90/10 Socket Weld Flanges

- Cupro Nickel 90/10 Weldoflange

- Cupro Nickel 90/10 ANSI Plate Flanges

- Cupro Nickel 90/10 Blind Flanges

- Cupro Nickel 90/10 Ring Type Joint Flanges

- Cupro Nickel 90/10 Lap Joint Flanges

- Cupro Nickel 90/10 Long Weld Neck Flanges

- Cupro Nickel 90/10 Backing Ring Flanges

- Cupro Nickel 90/10 Flangeolet

- Cupro Nickel 90/10 Raised Face Flanges

- Cupro Nickel 90/10 BS 10 Flanges

- Cupro Nickel 90/10 DIN Flanges

- Cupro Nickel 90/10 MSS SP-44 Flanges

- Cupro Nickel 90/10 ISO Flanges

- Cupro Nickel 90/10 UNI Flanges

- Cupro Nickel 90/10 EN 1092-1 Type 05 Flanges

- Cupro Nickel 90/10 AS/ANZ 4331.1 Flanges

- Cupro Nickel 90/10 Norwegian Flanges

- Cupro Nickel 90/10 BS 4504 Flanges

- Cupro Nickel 90/10 EN 1092-1 Flanges

- Cupro Nickel 90/10 Korean Flanges

- Cupro Nickel 90/10 EN 1092-1 Type 01 Flanges

- Cupro Nickel 90/10 EN 1092-1 Type 02 Flanges

- Cupro Nickel 90/10 Tongue and Groove Flanges

- Cupro Nickel 90/10 Male & Female Flanges

- Cupro Nickel 90/10 High Hub Blind Flanges

- Cupro Nickel 90/10 Reducing Flanges

- Cupro Nickel 90/10 Square Flanges

- Cupro Nickel 90/10 Expander Flanges

- Cupro Nickel 90/10 Vent Ring

- Cupro Nickel 90/10 EN 1092-1 Type 13 Flanges

- Cupro Nickel 90/10 JIS B2220 Flanges

- Cupro Nickel 90/10 Bleed Ring

- Cupro Nickel 90/10 API Flanges

- Cupro Nickel 90/10 BS4504 Threaded Flanges

- Cupro Nickel 90/10 BS4504 Plate Flanges

- Cupro Nickel 90/10 UNI Welding Neck Flanges

- Cupro Nickel 90/10 BS4504 Weld Neck Flanges

- Cupro Nickel 90/10 GOST Flanges

- Cupro Nickel 90/10 AWWA Flanges

- Cupro Nickel 90/10 UNI Plate Flanges

- Cupro Nickel 90/10 UNI Threaded Flanges

- Cupro Nickel 90/10 Drip Ring

- Cupro Nickel 90/10 BS4504 Blind Flanges

- Cupro Nickel 90/10 UNI Loose Flanges

- Cupro Nickel 90/10 UNI Blind Flanges

- Cupro Nickel 90/10 EN 1092-1 Type 11 Flanges

- Cupro Nickel 90/10 Flanges Manufacturers

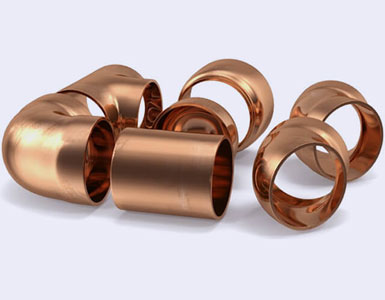

Copper Nickel 90/10 Similar Products

Copper Nickel 90/10 Flanges Applications

Copper Nickel Alloy 90/10 Flange is used to connect pipes, valves, pumps, and other equipment to form a piping system. Grade 90/10 Flanges also provide easy access for cleaning, inspection, or modification. It is usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

Cu-Ni 90/10 Flanges have 2 to 30% nickel, it is alloyed that has moderate strength and thermal stability in high-temperature levels as well as stress corrosion cracking resistance and high oxidation resistance.

Following are list of application industries where flanges are frequently used:

- Power Generation

- Offshore & Marine

- Offshore Oil and Gas Platforms and Processing

- Shipbuilding and Repair

- Chemical Processing

- Salt Water Pipes and Fittings

- Desalination Plants

- Seawater System Components

The wide range of applications demonstrates the robustness of UNS C70600 Flanges and how much this particular type of fitting is relied upon. We at Ample Alloys provide all necessary Material Testing Reports and Documentation and provide packaging of the products i.e. Grade 90/10 Industrial Flanges as per clients’ requirements or as per industry standards to keep products damage free during transit.

1 Comment

Pingback: Copper Nickel 70/30 Flanges Manufacturers, UNS C71500 Flange