Ample Alloys is globally accepted Manufacturers and Exporters of ASTM A815 Duplex 2205 Elbow, UNS S32205 Reducers, ANSI B16.9 Duplex Steel Tee, MSS-SP-43 Seamless Stub Ends, ASME B16.28 Butt Welding Bends, ASME SA815 DIN 1.4462 Cross, Grade 2205 End Caps.

Table of Content

- ASME SA815 Duplex 2205 Buttweld Pipe Fittings Specifications

- WERKSTOFF NR. 1.4462 Buttweld Pipe Fittings Chemical Composition

- UNS S32205 Buttweld Fittings Mechanical Properties

- Duplex Steel S32205 Buttweld Pipe Fittings Equivalent Material Grades

- ASTM A815 Grade 2205 Buttweld Pipe Fittings Types

- Duplex Alloy 2205 Similar Products

- Alloy S32205 Buttweld Fittings Features and Applications

- In Stock Pipe Fittings Duplex Grades

- ANSI Buttweld Fittings Dimensional Tolerances

- Weights of Butt Weld Fittings

- ASME B16.9 Buttweld Pipe Fittings Dimensions

Mumbai, India based Suppliers of Duplex Stainless Steel 2205 Pipe Fittings. Get Here Specifications, Dimensions, Type, Pressure Rating, Equivalent, Sizes, Weight Chart, Price List. Buy UNS S32205 Duplex Stainless Steel 45 Degree Elbow in Italy, Houston, Australia, USA, Japan, Kuwait, UK, Canada, Dubai, Qatar, Latin America.

Duplex S32205 Buttweld Pipe Fittings Specifications

- Material Grade: Duplex Alloy 2205

- Specifications: ASTM A815 / ASME SA815

- Welded Pipe Fittings Size Range: 1/2″ – 72″

- Seamless Butt Weld Fittings Size Range: 1/2″ – 24″

- Thickness Range: With NACE MR 01-75: Schedule 10, Schedule 40, Schedule 80, XS, XXS and SCH 160

- Standards: ANSI/ASME B16.9, MSS-SP-43/48/59, ASME B16.28, B16.25

- Grades: Duplex 2205 / 1.4462 / UNS S32205

- Type: Seamless Fittings / Welded Fittings / Fabricated Fittings

- Bending Radius: R= 1.5D, 1D, 2D, 3D, 5D, 6D, 8D, 10D

- International Specifications: WERKSTOFF NR. / UNS / JIS / BS / GOST / AFNOR / DIN / EN

Duplex 2205 Buttweld Pipe Fittings Chemical Composition:

| Element | Duplex S32205 |

|---|---|

| Ni | 4.50 – 6.50 |

| C | 0.030 max |

| Mo | 2.50 – 3.50 |

| Mn | 2.00 max |

| Si | 1.00 max |

| Fe | 63.54 min |

| N | 0.8 – 0.20 |

| S | 0.020 max |

| P | 0.030 max |

| Cr | 21.0 – 23.0 |

Duplex 2205 Pipe Fittings Mechanical Properties:

| Density | 7.8 g/cm3 |

|---|---|

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 116000 , MPa – 800 |

| Yield Strength (0.2%Offset) | Psi – 80000 , MPa – 550 |

| Elongation | 15 % |

Duplex 2205 Buttweld Pipe Fittings Equivalent Material Grades:

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Duplex 2205 | S32205 | 1.4462 |

Duplex Stainless Steel S32205 Buttweld Pipe Fittings Types

- Duplex 2205 45 Degree Elbow

- Duplex 2205 Short Stub End

- Duplex 2205 Seamless Pipe Bend

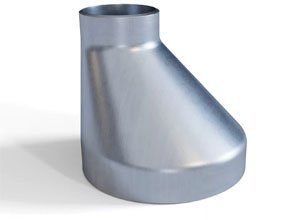

- Duplex 2205 Concentric Reducer

- Duplex 2205 Unequal/Reducing Cross

- Duplex 2205 Long Radius Elbow

- Duplex 2205 180° SR Elbow

- Duplex 2205 3D Elbow

- Duplex 2205 Equal Cross

- Duplex 2205 5D Elbow

- Duplex 2205 U Pipe Bend

- Duplex 2205 45° LR Elbow

- Duplex 2205 Long Stub End

- Duplex 2205 Long Radius Pipe Bend

- Duplex 2205 Mitered Pipe Bend

- Duplex 2205 90 Degree Elbow

- Duplex 2205 Short Radius Elbow

- Duplex 2205 End Caps

- Duplex 2205 Piggable Pipe Bend

- Duplex 2205 5D Pipe Bend

- Duplex 2205 Hot Induction Pipe Bend

- Duplex 2205 3D Pipe Bend

- Duplex 2205 1D Elbow

- Duplex 2205 Unequal/Reducing Tee

- Duplex 2205 1.5D Elbow

- Duplex 2205 180° LR Elbow

- Duplex 2205 Eccentric Reducer

- Duplex 2205 90° SR Elbow

- Duplex 2205 180 Degree Elbow

- Duplex 2205 90° LR Elbow

- Duplex 2205 Equal Tee

- Duplex 2205 10D Pipe Bend

- Duplex 2205 J Pipe Bend

- Duplex 2205 45° SR Elbow

- Duplex 2205 Lap Joint Stub End

- Duplex 2205 Welded Pipe Bend

Duplex Steel S32205 Similar Products

Duplex S32205 Buttweld Pipe Fittings Features and Applications

Duplex 2205 buttweld fittings features super plasticity and excellent pitting corrosion resistance. Compared with ferrite, Duplex Steel has a better toughness, intergranular corrosion resistance, plasticity, iron retention, and weldability. Duplex features high strength and excellent resistance to chloride stress corrosion and intergranular corrosion, In comparison with Austenitic stainless steel. Like Ferrite Duplex Stainless Steel maintains high thermal conductivity and the brittleness at 475°C, yet it is free from room temperature brittleness. Some Applications of Duplex Steel are as follow:

- Chemical processing, storage and transport

- Marine environments

- petroleum and natural gas

- construction industry

- Pulp & paper manufacturing

- Chemical process plant

- biofuels

- Oil and gas refining

- Structural and mechanical components

- Pipe fittings for production and transportation of oil and gas

We at Ample Alloys provide all necessary Material Testing Report and Documentation and provide packaging of the products i.e. UNS S32205 Buttweld Fittings as per clients requirement or as per industry standards to keep products damage free during transit.