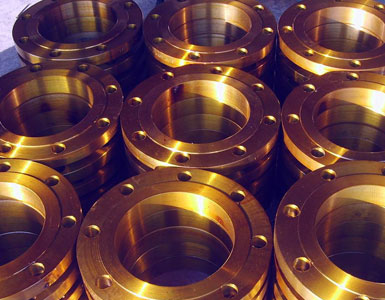

Ample Alloys is globally accepted Manufacturers and Exporters of ASTM B366 Copper Nickel 70/30 Buttweld Fittings, Cu-Ni 70/30 Cross, DIN 2.0882 Elbow, UNS C71500 Copper Alloy 70/30 Reducers, ANSI B16.9 Tee, MSS-SP-43 End Caps, Grade 70/30 Seamless Stub Ends, 3D Pipe Bends.

Table of Content

- ASTM B366 Cu-Ni 70/30 Buttweld Fittings Specifications

- UNS C71500 Pipe Fittings Chemical Composition

- WERKSTOFF NR. 2.0882 Buttweld Fittings Mechanical Properties

- Copper 70/30 Buttweld Fittings Equivalent Material Grades

- ASME SB366 Cu-Ni 70/30 Buttweld Fittings Types

- Copper Nickel Alloy 70/30 Fittings Similar Products

- Copper Alloy 70/30 Buttweld Fittings Applications

- In Stock Buttweld Fittings Copper Grades

- ANSI Buttweld Fittings Dimensional Tolerances

- ASME B16.9 Butt Weld Fittings Dimensions

- Buttweld Fittings Weights Chart

Mumbai, India based Suppliers of ASME SB366 Cupro Nickel 70/30 Buttweld Fittings. Get Here Dimensions, Type, Specifications, Pressure Rating, Weight Chart, Equivalent, Price List, Sizes. Buy UNS C71500 Copper 45 Degree Elbow in Italy, USA, Canada, Qatar, Australia, Latin America, Kuwait, Dubai.

Copper Nickel 70/30 Buttweld Pipe Fittings Specifications

- Seamless Butt Weld Fittings Size: 1/2″ – 24″

- Welded Pipe Fittings Size: 1/2″ – 72″

- Specifications: ASTM B366 / ASME SB366

- Type: Seamless Fittings / Welded Fittings / Fabricated Fittings

- International Specifications: WERKSTOFF NR. / UNS / JIS / BS / GOST / AFNOR / DIN / EN

- Material Grade: Cu-Ni 70/30

- Standards: ANSI/ASME B16.9, MSS-SP-43/48/59, ASME B16.28, B16.25

- Bending Radius: R= 10D, 8D, 6D, 5D, 3D, 2D, 1D, 1.5D

- Grades: Copper 70/30 / 2.0882 / UNS C71500

- Thickness Range: With NACE MR 01-75: Schedule 10, Schedule 40, Schedule 80, XS, XXS and SCH 160

Copper Nickel 70/30 Pipe Fittings Chemical Composition:

| Grade | Cu-Ni 70/30 |

|---|---|

| Ni | 29 – 33 |

| Zn | 1 max |

| Fe | 0.4-1.0 |

| Mn | 1.0 max |

| Pb | 0.05 max |

| Cu | 65.0 min |

Copper Nickel 70/30 Pipe Fittings Mechanical Properties:

| Grade | Cu-Ni 70/30 |

|---|---|

| Elongation | 30 % |

| Density | 0.323 lb/in3 at 68 F |

| Melting Point | 2260 F |

| Yield Strength (0.2%Offset) | 20000 psi |

| Tensile Strength | 50000 psi |

Copper Nickel 70/30 Buttweld Fittings Equivalent Material Grades:

| UNS | WERKSTOFF NR. |

|---|---|

| C71500 | 2.0882 |

Copper Nickel 70/30 Buttweld Pipe Fittings Types

- Copper Nickel 70/30 Seamless Pipe Bend

- Copper Nickel 70/30 3D Elbow

- Copper Nickel 70/30 Mitered Pipe Bend

- Copper Nickel 70/30 45 Degree Elbow

- Copper Nickel 70/30 Long Radius Elbow

- Copper Nickel 70/30 Equal Cross

- Copper Nickel 70/30 Short Stub End

- Copper Nickel 70/30 10D Pipe Bend

- Copper Nickel 70/30 45° SR Elbow

- Copper Nickel 70/30 Short Radius Elbow

- Copper Nickel 70/30 Welded Pipe Bend

- Copper Nickel 70/30 45° LR Elbow

- Copper Nickel 70/30 End Caps

- Copper Nickel 70/30 Concentric Reducer

- Copper Nickel 70/30 90° SR Elbow

- Copper Nickel 70/30 180 Degree Elbow

- Copper Nickel 70/30 90 Degree Elbow

- Copper Nickel 70/30 U Pipe Bend

- Copper Nickel 70/30 Piggable Pipe Bend

- Copper Nickel 70/30 3D Pipe Bend

- Copper Nickel 70/30 5D Elbow

- Copper Nickel 70/30 Unequal/Reducing Tee

- Copper Nickel 70/30 1D Elbow

- Copper Nickel 70/30 Long Radius Pipe Bend

- Copper Nickel 70/30 Lap Joint Stub End

- Copper Nickel 70/30 1.5D Elbow

- Copper Nickel 70/30 5D Pipe Bend

- Copper Nickel 70/30 Equal Tee

- Copper Nickel 70/30 90° LR Elbow

- Copper Nickel 70/30 Eccentric Reducer

- Copper Nickel 70/30 Hot Induction Pipe Bend

- Copper Nickel 70/30 Unequal/Reducing Cross

- Copper Nickel 70/30 J Pipe Bend

- Copper Nickel 70/30 180° SR Elbow

- Copper Nickel 70/30 Long Stub End

- Copper Nickel 70/30 180° LR Elbow

Copper Alloy 70/30 Similar Products

Copper Alloy 70/30 Buttweld Fittings Applications

Cu-Ni 70/30 has an excellent resistance to erosion and corrosion. It is a mixture of 30% nickel and 70% copper with contents of manganese and iron. it has slightly enhanced strength level than alloy 90/10. With all these characteristics grade 70/30 is a perfect fit for more demanding applications.

- Marine Sector

- Offshore Oil and Gas

- Power Generation

- Desalination

- Cooling Plants

- Submarine and Seawater Pipework

- Offshore Firewater Systems

We at Ample Alloys provide all necessary Material Testing Report and Documentation and provide packaging of the products i.e. UNS C71500 Butt Welding Fittings as per clients requirement or as per industry standards to keep pipe fittings damage free during transit.