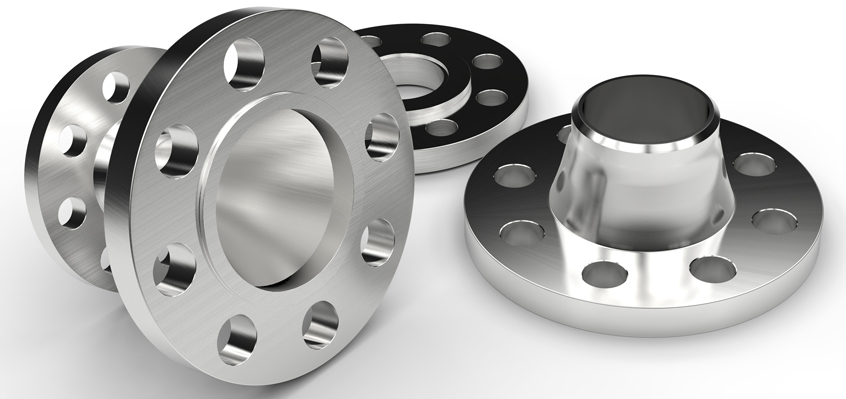

Industrial Pipe Flange (ANSI B16.5 / ASME B16.47) – Manufacturers & Stockist

Manufactured ASME/ANSI B16.5/B16.47 Flanges at our Factory in Mumbai, India

We Recognize as a Trusted Manufacturers, Suppliers, & Exporters of Industrial Pipe Flange in Class 300Lb, 600Lb, 900Lb, 1500Lb, 2500Lb, DIN 2527/2576/2632/2633/2634/2635/2642.

Materials used in manufacturing of Industrial Pipe Flange includes Stainless Steel(SS), Hastelloy, Monel, Inconel, Titaniun, Duplex Steel, Nickel Alloy, Super Duplex Steel, Incoloy, Alloy 20, 254 SMO, Copper Nickel, Carbon Steel(CS), Alloy Steel, Aluminium, Bronze, Mild Steel(MS), Brass.

- Standard Specifications of Industrial Pipe Flange

- Materials, Standards, & Grades of Industrial Pipe Flange

- Available Types of Industrial Pipe Flange

- Dimensions of Industrial Pipe Flange

- Industries We Caters Industrial Pipe Flange

- Country List where we Export & Supply

- City List where we Export & Supply

- Check & Buy Ready Stock of Industrial Pipe Flange

- Manufacturing Process of Industrial Pipe Flange

- Price Range of Industrial Pipe Flange in India

Table Of Content:

Experts in Manufacturing of:

- Stainless Steel(SS) Industrial Pipe Flange

- Hastelloy Industrial Pipe Flange

- Monel Industrial Pipe Flange

- Inconel Industrial Pipe Flange

- Titaniun Industrial Pipe Flange

- Duplex Steel Industrial Pipe Flange

- Nickel Alloy Industrial Pipe Flange

- Super Duplex Steel Industrial Pipe Flange

- Incoloy Industrial Pipe Flange

- Alloy 20 Industrial Pipe Flange

- 254 SMO Industrial Pipe Flange

- Copper Nickel Industrial Pipe Flange

- Carbon Steel(CS) Industrial Pipe Flange

- Alloy Steel Industrial Pipe Flange

- Aluminium Industrial Pipe Flange

- Bronze Industrial Pipe Flange

- Mild Steel(MS) Industrial Pipe Flange

- Brass Industrial Pipe Flange

ETC.

Standard Specifications of Industrial Pipe Flange

- Type Industrial Pipe Flange

- Size ½” (15 NB) to 48″ (1200NB)

- Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- DIN DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

- BS BS4504 , BS4504, BS1560, BS10

- In Form SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle, etc

- Specialize As per drawing

- Standard ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820

- Coating/Surface Treatment Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

- Connection Type Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large, Tongue & Groove, Small Tongue & Groove

- Flange Face Type Flat Face (FF), Raise Face (RF), Ring Joint (RJT)

- Dimensions ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Packing No Fumigate or Fumigate Plywood/Wood Pallet or Case

- Usage/Applications Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc.

Materials, Standards, & Grades of Industrial Pipe Flange

- Stainless Steel Flanges ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L

- Duplex Steel Flanges ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

- Super Duplex Flanges ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

- Nickel Alloys Flanges ASTM SB564, SB160, SB472, SB162 – Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

- Copper Alloys Flanges ASTM SB 61 , SB62 , SB151 , SB152 – UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

- Alloys Flanges ALLOY 20, ALLOY C, ALLOY C276, ALLOY B2

- Low Temperature Steel Flanges ASTM A350 LF2, LF3, LF6

- High Yield Flanges ASTM A694 F42, F52, F60, F65, F70

- Carbon Steel Flanges ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52

- Alloy Steel Flanges ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

We have given an impetus to several industries during the past two decades, especially through its extraordinary services and outstanding products. As an ISO certified Industry that caters to the demanding requisites of some of the most critical industries. Stainless Steel Flanges have bores with a diameter slightly larger than the pipe; this helps it to slide\slip over the pipe. This Industrial Pipe Flange(ASME/ANSI B16.5/B16.47) is then welded inside and outside too, with fillet welding. We supply Flanges in both raised face and flat faced designs, to industries like agricultural, fertilisers, pharmaceutical, textile and for general engineering purposes.

Available Types of Industrial Pipe Flange

Weld Neck Flange:

A weld neck flange (also known as a high-hub flange and tapered hub flange) is a type of flange. There are two designs. The regular type is used with pipes. The long type is unsuitable for pipes and is used in process plant. Know More

A weld neck flange (also known as a high-hub flange and tapered hub flange) is a type of flange. There are two designs. The regular type is used with pipes. The long type is unsuitable for pipes and is used in process plant. Know More

Slip-on Flanges:

Slip on pipe flanges are typically provided with a raised or flat face. When a raised face is necessary for slip on pipe flanges, the standard height is 1/16″ for slip on pipe flanges under 400#. For slip on pipe flanges of 400# and up, the standard slip on pipe flange raised face height is 1/4″. Know More

Slip on pipe flanges are typically provided with a raised or flat face. When a raised face is necessary for slip on pipe flanges, the standard height is 1/16″ for slip on pipe flanges under 400#. For slip on pipe flanges of 400# and up, the standard slip on pipe flange raised face height is 1/4″. Know More

Lap Joint Flange:

Lap joint flange use a stub end that is welded to the pipe. A ring flange fits loosely around the stub end, permitting easy flange alignment of the bolt holes. A lap joint flange is also called Van Stone or Stub Flange. The stub ends are available in three styles (Types A, B, and C) and two lengths (Short and Long). Know More

Lap joint flange use a stub end that is welded to the pipe. A ring flange fits loosely around the stub end, permitting easy flange alignment of the bolt holes. A lap joint flange is also called Van Stone or Stub Flange. The stub ends are available in three styles (Types A, B, and C) and two lengths (Short and Long). Know More

Blind Flange:

A blind flange is a solid flange as shown in above Picture. The purpose of these is to block off a section of pipe or a nozzle on a vessel that is not used. (A nozzle is typically a pipe coming out of a vessel and is usually flanged so it can be connected to valves or piping). Know More

A blind flange is a solid flange as shown in above Picture. The purpose of these is to block off a section of pipe or a nozzle on a vessel that is not used. (A nozzle is typically a pipe coming out of a vessel and is usually flanged so it can be connected to valves or piping). Know More

Threaded Flange:

Threaded Flange are also known as a screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. Threaded Flanges are mostly used in utility services such as air and water. Know More

Threaded Flange are also known as a screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. Threaded Flanges are mostly used in utility services such as air and water. Know More

Socket Weld Flange:

Socket weld flange are typically used on smaller sizes of high-pressure pipes. These socket-weld pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. Know More

Socket weld flange are typically used on smaller sizes of high-pressure pipes. These socket-weld pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. Know More

Ring Type Joint Flange:

A Ring Type Joint Flange is a type of flange that uses a metal ring that sits in a hexagonal groove as a gasket to seal the flange pair. The flanges seal when the bolts are tightened and the gasket is compressed into the groove making a metal to metal seal. Know More

A Ring Type Joint Flange is a type of flange that uses a metal ring that sits in a hexagonal groove as a gasket to seal the flange pair. The flanges seal when the bolts are tightened and the gasket is compressed into the groove making a metal to metal seal. Know More

Flat Flange:

The Flat flange has a gasket surface in the same plane as the bolting circle face. It is also known as flat face flange. Applications using flat face flanges are frequently those in which the mating flange or flanged fitting is made from a casting. Flat face flanges are used when the counter-flanges are flat face. Know More

The Flat flange has a gasket surface in the same plane as the bolting circle face. It is also known as flat face flange. Applications using flat face flanges are frequently those in which the mating flange or flanged fitting is made from a casting. Flat face flanges are used when the counter-flanges are flat face. Know More

Spectacle Blind Flange:

Spectacle and line blind flange are similar to a blind flange but different because they fit between two flanges. Spectacle blind gets their name from similarity to pair or eye glasses. Once side of Spectacle Blind Flange is fully closed for complete flow shuts off, whereas the other end is open for full flow. Know More

Spectacle and line blind flange are similar to a blind flange but different because they fit between two flanges. Spectacle blind gets their name from similarity to pair or eye glasses. Once side of Spectacle Blind Flange is fully closed for complete flow shuts off, whereas the other end is open for full flow. Know More

Orifice Flange:

Orifice Flanges are used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Pairs of pressure “Tappings”, mostly on 2 sides, directly opposite each other, are machined into the orifice flange. Know More

Orifice Flanges are used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Pairs of pressure “Tappings”, mostly on 2 sides, directly opposite each other, are machined into the orifice flange. Know More

Reducing Flange:

Reducing flange are a specialty flange that is most often used on projects that require the fitting together of different sized pipes. There are several types of reducing flanges including weld-neck reducing flanges, slip-on reducing flanges and threaded reducing flanges. Know More

Reducing flange are a specialty flange that is most often used on projects that require the fitting together of different sized pipes. There are several types of reducing flanges including weld-neck reducing flanges, slip-on reducing flanges and threaded reducing flanges. Know More

Square Flange:

Square Flange made in accordance to JIS B2291 standard is a connecting piece that links JIS (Japanese Industrial Standards) nominal bore size pipes together and has a working pressure of up to 210kgf/cm2. This is equivalent to 210 Bar, or 21MPa. Know More

Square Flange made in accordance to JIS B2291 standard is a connecting piece that links JIS (Japanese Industrial Standards) nominal bore size pipes together and has a working pressure of up to 210kgf/cm2. This is equivalent to 210 Bar, or 21MPa. Know More

High Hub Flange:

The High Hub Blind Flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This high hub blind flange is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles. Know More

The High Hub Blind Flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This high hub blind flange is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles. Know More

Spade and Ring Spacer Flange:

Spade and Ring Spacer Flange are basically the same as Spectacle Blinds, except that they both are not attached to each other. Spades and Spacers be used in systems where the maintenance is not often necessary, or it is also used in applications with large pipe sizes. Know More

Spade and Ring Spacer Flange are basically the same as Spectacle Blinds, except that they both are not attached to each other. Spades and Spacers be used in systems where the maintenance is not often necessary, or it is also used in applications with large pipe sizes. Know More

Tongue & Groove Flange:

Tongue & Groove Flange are referred to as either Groove & Tongue or Tongue. This is similar to a slip-on flange in outline, but the bore is Groove & Tongue, thus enabling assembly without welding. These threads are tapered in order to create a seal between the Groove & Tongue flange and the pipe as the tapers approach the same diameter. Know More

Tongue & Groove Flange are referred to as either Groove & Tongue or Tongue. This is similar to a slip-on flange in outline, but the bore is Groove & Tongue, thus enabling assembly without welding. These threads are tapered in order to create a seal between the Groove & Tongue flange and the pipe as the tapers approach the same diameter. Know More

Long Neck flange:

Long Neck Welding flange (LWN) are similar to a standard Welding Neck flange, but the “Neck” is considerably longer. These Long Weld Neck Flange is often used as a nozzle for a barrel or column. In addition, there are the type LWN Heavy Barrel (HB) and the Equal LWN Barrel (E); they have a different shape and a thicker “Wall”. Know More

Long Neck Welding flange (LWN) are similar to a standard Welding Neck flange, but the “Neck” is considerably longer. These Long Weld Neck Flange is often used as a nozzle for a barrel or column. In addition, there are the type LWN Heavy Barrel (HB) and the Equal LWN Barrel (E); they have a different shape and a thicker “Wall”. Know More

Nipoflange / Weldoflange:

The Nipoflange / Weldoflange is a combination of a Welding Neck flange and a supposedly Weldolet or Nipolet. On the run pipe side a nipoflange is designed like a weldolet. That means the branch connection on the run pipe side is a welding connection. On the other side, it has a flange connection. Know More

The Nipoflange / Weldoflange is a combination of a Welding Neck flange and a supposedly Weldolet or Nipolet. On the run pipe side a nipoflange is designed like a weldolet. That means the branch connection on the run pipe side is a welding connection. On the other side, it has a flange connection. Know More

Expander Flange:

An Expander Flange is a type of welding neck pipe flange used to increase pipe size at the flange connection. If you have limited space or just need to connect to a larger pipe size, it provides a convenient way for equipment, pumps and valves. Know More

An Expander Flange is a type of welding neck pipe flange used to increase pipe size at the flange connection. If you have limited space or just need to connect to a larger pipe size, it provides a convenient way for equipment, pumps and valves. Know More

Dimensions of Industrial Pipe Flange

150 Lb Flange Dimensions | 300 Lb Flange Dimensions | 600 Lb Flange Dimensions | 900 Lb Flange Dimensions | 1500 Lb Flange Dimensions | 2500 Lb Flange Dimensions | Welding Neck Flange Bores | DIN 2527 Flange | DIN 2576 Flange | DIN 2632 Flange | DIN 2633 Flange | DIN 2634 Flange | DIN 2635 Flange | DIN 2642 Flange

Industries We Caters Industrial Pipe Flange

Ample Alloys has many years of experiance of export and supply of Industrial Pipe Flanges that is extensively used in the following industries:

- Refineries

- Gas Processing

- Off-Shore Oil Drilling Companies

- Petrochemicals

- Hydro-Carbon

- Fertilizers

- Paper & Pulp Companies

- Power Generation

- Specialty Chemicals

- Pharmaceuticals

- Drugs

- Steel

- Cement

- Water Pipe Line

- Pesticides

- General Piping

- Construction

- Engineering

- Nuclear

- Food Processing & Dairy

- boiler & heatexchangers

City List where we Export & Supply

|

|

|

|

Country List where we Export & Supply

|

|

|

|

Price Range of Industrial Pipe Flange in India

Prices varies frequently and also depends on minimum order and might changed without any prior notifications. For more details contact us now and get Instant Quote.

- ANSI B16.5 FLANGE CS WN : US $1.00-$50.00 / Piece

- ss304/304l jis 10k soff flanges : US $1.00-$100.00 / Piece

- ASME B16.5 SS Welded DIN2545 Flange : $7.80-$18.90 / Piece

- duplex steel uns32750 flange : $3.20-$24.50 / Piece