ASME B16.11 Socket Weld Reducing Tee Manufacturers in Mumbai India

Manufactured Socket Weld Reducing Tee Pipe Fittings at our Factory in India

We Recognize as a Trusted Manufacturers, Suppliers, & Exporters of Stainless Steel Socket Weld Reducing Tee – ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 in all Dimensions and sizes.

Materials used in manufacturing of Forged Socket Weld Reducing Tee includes Stainless Steel, Duplex & Super Duplex Steel, Nickel Alloy, Copper Alloy, Carbon Steel, Alloy Steel, Hastelloy, Monel, Inconel, Titaniun, Incoloy, Alloy 20, 254 SMO, Mild Steel(MS), Brass.

Table Of Content:

- Socket Weld Reducing Tee Specifications

- Socket Weld Reducing Tee Materials

- What is a Socket Weld Reducing Tee?

- Socket Weld Reducing Tee Manufacturing Standards

- Socket Weld Reducing Tee Types

- ASME B16.11 Socket Weld Reducing Tee Dimensions

- Socket Weld Reducing Tee Applications

- Cities we Supply Socket Weld Reducing Tee

- Countries we Export Socket Weld Reducing Tee

Experts in Manufacturing of:

-

- Stainless Steel(SS) Socket Weld Reducing Tee

- Hastelloy Socket Weld Reducing Tee

- Monel Socket Weld Reducing Tee

- Inconel Socket Weld Reducing Tee

- Titaniun Socket Weld Reducing Tee

- Duplex Steel Socket Weld Reducing Tee

- Nickel Alloy Socket Weld Reducing Tee

- Super Duplex Socket Weld Reducing Tee

- Incoloy Socket Weld Reducing Tee

- Alloy 20 Socket Weld Reducing Tee

- 254 SMO Socket Weld Reducing Tee

- Copper Nickel Socket Weld Reducing Tee

- Carbon Steel(CS) Socket Weld Reducing Tee

- Alloy Steel Socket Weld Reducing Tee

- Aluminium Socket Weld Reducing Tee

- Bronze Socket Weld Reducing Tee

- Mild Steel(MS) Socket Weld Reducing Tee

- Brass Socket Weld Reducing Tee

ETC.

Standard Specifications of Socket Weld Reducing Tee

- Dimensions ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

- Size 1/2″NB TO 4″NB IN

- Pressure Class 3000 LBS, 6000 LBS, 9000 LBS

- Type Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

- Value Added Services Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering

- Production Grades Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel

Materials and Grades of ASME B16.11 Socket Weld Reducing Tee

- ASME B16.11 Stainless Steel Socket Weld Reducing Tee Pipe Fittings ASTM / ASME A/SA 182 – F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

- ASME B16.11 Duplex & Super Duplex Socket Weld Reducing Tee Pipe Fittings ASTM / ASME A/SA 182 – F44, F45, F51, F53, F55, F60, F61.

- ASME B16.11 Nickel Alloy Socket Weld Reducing Tee Pipe Fittings ASTM / ASME SB 564 / 160 / 472 – UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600(INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3)

- ASME B16.11 Copper Alloy Socket Weld Reducing Tee Pipe Fittings ASTM / ASME SB 61 / 62 / 151 / 152 – UNS NO. C 92200, UNS NO. C 83600, UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200

- ASME B16.11 Carbon Steel Socket Weld Reducing Tee Pipe Fittings ASTMA 105/A694/ A350 LF3/A350 LF2 – F42, F46, F52, F56, F60, F65, F70

- ASME B16.11 Alloy Steel Socket Weld Reducing Tee Pipe Fittings ASTM A182 – F1, F5, F9, F11, F22, F91

- ASME B16.11 Brass Socket Weld Reducing Tee Pipe Fittings Brass CA 360, CA 345 and CA 377 / SAE J530, SAE J531 and ASA

What is a ASME B16.11 Socket Weld Reducing Tee?

Ample Alloys are highly professional in manufacturing of Forged Reducing Tees Pipe Fittings. It is also known as Unequal Tee Forged Fittings mainly a high-pressure three-way pipe connecting fitting which is formed by forming a round forged steel or steel ingot and then forming it by a lathe machine. According to the common standards, the specifications of the three-way socket are DN6, DN8, DN10, DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80 and DN100. The primary purpose of a Tee is to make a 90° branch from the main run of pipe. The reducing tee is used as the branch has a smaller diameter as the run-pipe.

Socket Weld Reducing Tee Manufacturing Standards

- ASME ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

- DIN DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

- EN EN10253-1, EN10253-2

Types of ASME B16.11 Socket Weld Reducing Tee

| Forged Socket weld Unequal Tee | Forged Socket weld Reducing Tees |

| Stainless Steel Unequal Tee | Socket weld Forged Reducing Tee |

| Hastelloy Socket weld Unequal Tee | Inconel Socket weld Unequal Tee |

| SS Forged Socket weld Unequal Tees | BS 3799 Forged Unequal Tee |

| Carbon Steel Socket weld Unequal Tee | High Quality Socket weld Unequal Tee |

| ASTM A182 Socket weld Unequal Tees | Duplex Steel Socket weld Unequal Tee |

| Super Duplex Steel Unequal Tee | Copper Nickel Socket weld Unequal Tee |

| ASME B16.11 Forged Socket weld Unequal Tee | Forged Unequal Tee 3000LB Socket Weld |

| 150 lb. Socket Weld Fittings Unequal Tee | ANSI B16.11 Forged Socket weld Unequal Tee |

| High Nickel Alloy Forged Steel Reducing Tee | Titanium Forged Socket weld Unequal Tee |

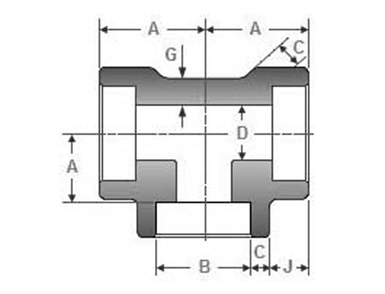

ASME B16.11 Socket Weld Unequal / Reducing Tee Dimensions

NPS 1/2 to 4 – Class 3000:

| NPS | Socket Bore | Depth Socket | Bore dia |

|---|---|---|---|

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

Class 6000 NPS 1/2 to 2:

| NPS | Socket Bore | Depth Socket | Bore dia |

|---|---|---|---|

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 6.95 6.05 |

5.55 | 22.5 |

| 1 | 7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 8.90 7.80 |

7.15 | 38 |

| 2 | 10.90 9.50 |

8.75 | 41 |

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- Socket Bore (B) – Maximum and minimum dimensions.

- Bore Diameter (D) – Maximum and minimum dimensions.

- Socket wall thickness – (C) – Average of Socket wall thickness.

- Dimensional tolerances center to bottom of socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2.1/2 to NPS 4 = +/- 2.5 mm

Industries We Caters Industrial Socket Weld Reducing Tee

Ample Alloys & Tubes has many years of experiance of export and supply of ASME B16.11 Socket Weld Reducing Tee Pipe Fittings that is extensively used in the following industries:

- Refineries

- Gas Processing

- Off-Shore Oil Drilling Companies

- Petrochemicals

- Hydro-Carbon

- Fertilizers

- Paper & Pulp Companies

- Power Generation

- Specialty Chemicals

- Pharmaceuticals

- Drugs

- Steel

- Cement

- Water Pipe Line

- Pesticides

- General Piping

- Construction

- Engineering

- Nuclear

- Food Processing & Dairy

- boiler & heatexchangers

City List where we Export & Supply

|

|

|

|

Country List where we Export & Supply

|

|

|

|